iUMTEK: an instrument for in-depth analysis of matter

At the intersection between photonics and artificial intelligence, start-up iUMTEK is developing cutting-edge instruments. With the ability to detect and quantify all the elements of Mendeleev's periodic table, from samples or even directly within the production process, the proposed technology promises to answer the questions of manufacturers working in the context of the circular economy.

In October 2017, engineer Ronald Berger-Lefébure founded the start-up iUMTEK, in partnership with CEA Investissement, a subsidiary of the French Alternative Energies and Atomic Energy Commission (CEA) which also co-founded this start-up with which it has a patent use agreement*. "We were originally four employees who met during previous professional experience," explains iUMTEK's Founder and President. “We wanted to provide instrumental solutions, based on photonics and artificial intelligence (AI), to contribute to global concerns: increasing the rate of recyclability (Li-ion batteries, etc.) and short circuits, combating risks (e.g. monitoring SEVESO sites) and pollution (nanoparticles, smoke control, etc.), optimising industrial production and the mining of critical and strategic materials, developing green chemistry and a new nuclear power."

A 2019 winner of the i-Lab competition run by the French Ministry of Higher Education and Research, iUMTEK was awarded the Greentech label by the French Ministry of Ecological Transition the following year. After two years of hosting by IncubAlliance, the technology incubator on the Paris-Saclay campus, in 2020 iUMTEK became one of the first four companies to join Accelair, the Air Liquide Group's deeptech start-up accelerator. In 2023, it joined CentraleSupélec's Scale'up campus in Gif-sur-Yvette. Following the renovation of this campus, iUMTEK moved to the new 503, the Institut d'Optique Graduate School's centre for entrepreneurship and innovation, and is now based in Orsay. In addition to the support offered by the host structures, iUMTEK benefits from the backing of BPIFrance, Team France Export, French Tech Paris-Saclay, the Systematic Paris-Region competitiveness cluster and the Île-de-France region.

Technology combining photonics and AI

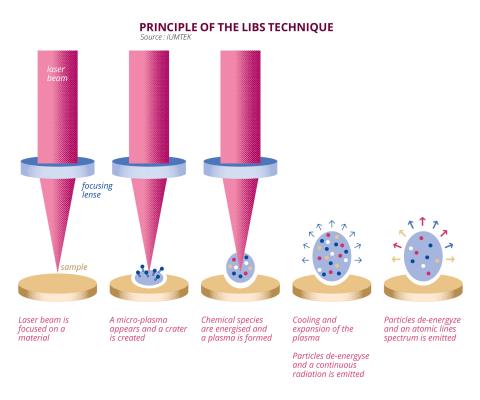

Currently employing around ten people, including interns and a PhD candidate, the start-up designs and manufactures measurement instruments based on LIBS (Laser Induced Breakdown Spectroscopy) technology. This technology identifies and quantifies the atoms of all types of materials. "To operate, our instrument produces a laser beam that interacts physically and chemically with matter, creating a plasma. The emitted and detected spectra contain a multitude of emission lines. The wavelengths are intertwined and even overlapped by other lines of more emissive chemical elements. Machine learning enables a reliable and reproducible interpretation and reduces the level of uncertainty," explains Ronald Berger-Lefébure. Thanks to their 25 years' experience in the field, the team members are able to accurately determine which algorithm is best suited to the situation, in order to identify and quantify the selected chemical elements.

The data collected is gigantic. In fact, the instrument is capable of taking measurements in a wide variety of environments, and of studying all 118 elements in Mendeleev's periodic table of elements. Samples require no prior preparation and can be analysed regardless of the material's state (liquid, solid or gas).

"In-situ" analysers

The technology is proving popular, as the young company has already sold its TX 1000 LIBS analysers to research and development laboratories in France, Israel and the USA.

LIBS technology, based on optics, is able to carry out remote analyses, at a distance of up to several meters. This is a considerable advantage, since for certain hazardous activities, such as radioactivity or molten metal baths, measurements must be taken remotely. If required, "the entire LIBS technique can be carried out by optical fibre, in order to obtain a lightweight analysis probe (≈ 1.5 kg). It can be used over a radius of several meters around the instrument thus allowing analyses in areas that are not easily accessible," explains iUMTEK's President and Founder.

Finally, the instrument can also be installed on a production line, for real-time measurements. The aim is to keep track of a flow thus leading to continuous monitoring. "We're aiming to bring to market a system that is ten to thirty times faster than other methods. Our tool is capable of analysing materials in situ and identifying atoms not detected by conventional measuring instruments," adds Ronald Berger-Lefébure.

Serving the circular economy

With such capabilities, iUMTEK covers a particularly wide field of analysis. "We want to embed this technology at the heart of industrial processes, to optimise them at every stage, taking a circular economy approach. This applies, for example, to new nuclear power, electric vehicles, through the detection of lithium in the manufacturing cycle and battery processing, the green hydrogen field of study and copper recycling. These analyses will prevent raw materials and energy being wasted, and excessive downstream carbon dioxide emissions," explains Ronald Berger-Lefébure.

In a large group, the start-up is able to install its tool within twelve months, the time it takes for the hierarchy to validate the relevance of the analysis campaigns, integrate the technology and carry out in-situ tests. Even if it takes time to set up, it's well worth the effort: "Those who have issues with production quality and profitability are aware of what we can do for them. Don't hesitate to contact us. We have a co-development approach that benefits everyone," says the President and Founder.

In the first half of 2025, iUMTEK will launch a fundraising round of three to five million euros from deeptech/cleantech investors.

*iUMTEK holds five patents on the CEA's LIBS technology (including one jointly with ORANO).